PROCESS VIDEO 03 – ASSEMBLY

Assembling the product properly sets the project up for success. Michael will walk you through why that’s the case.

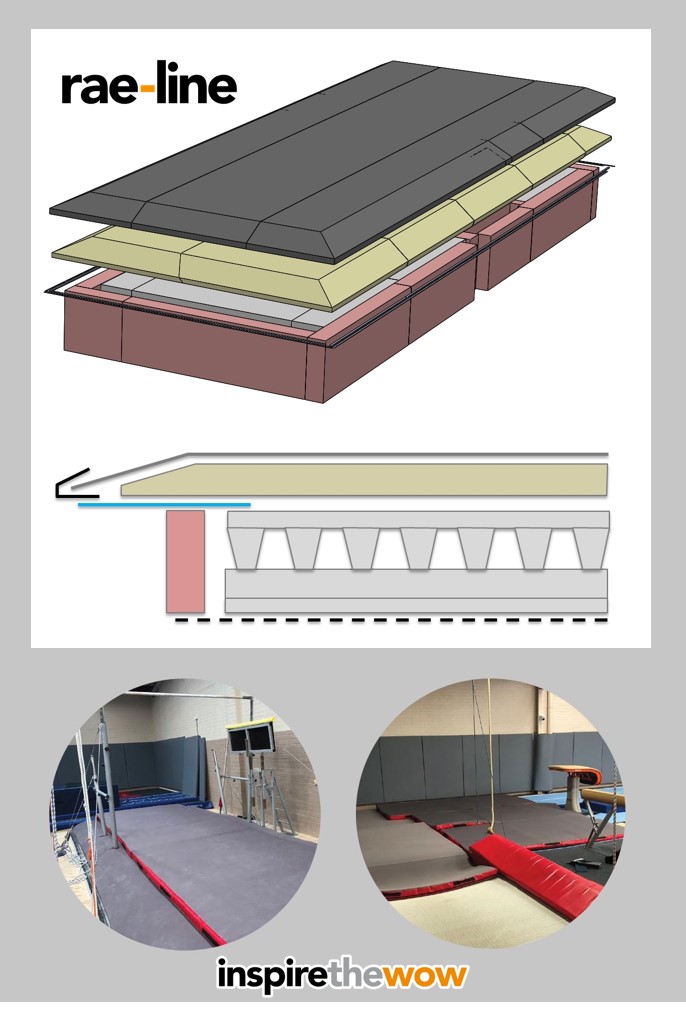

Assembly is about lining all your ducks up in a row. All of the sewn covers and carpet tops from the cutting stage are matched up with the foam pieces and are stuffed and glued together.

To minimise assembly mistakes, we use a barcode system to ensure all the pieces match up. Once the pieces are assembled they enter our quality control booth where each individual piece is examined to ensure the quality of the product.

We look at the overall form of the piece and ensure the details such as the colours, zips, and velcro meet the original brief’s specifications. Once it’s approved, it is prepared for shipping and installation.

Assembling the product correctly is about ensuring the quality and maintaining efficiency with time. Avoiding installation delays are key to delivering a good product. We aim to ensure that everything that leaves the factory as it’s specified in the design.

If there’s more that you’d like to know, don’t hesitate to get in touch. Give us a call, or visit our website.